|  |

Natural diamond is the hardest material in the world, which has high hardness, good thermal conductivity and thermal performance, and is widely used in industrial field. Its physical properties are: density 3.515g/cm3; hardness: 1.25-10.76GPa.

Diamond wire drawing die of natural diamond wire drawing die for La type diamond. This kind of diamond contains a certain amount of nitrogen impurities (0.1% orders of magnitude), and the synthesis of small aggregates of these nitrogen impurities. At the same time, it also contains small pieces (in connection with nitrogen impurities), the precise structure of these small pieces of unknown.

Tianchang City Hengtong metal products Co., Ltd. is the production of natural diamond drawing die material in high quality natural diamond materials, undergo a rigorous selection and processing. High surface finish, good wear resistance is its main advantages. Suitable for high surface quality requirements of various types of wire drawing.

Because there are some defects that can not be observed in natural diamond, the difference of the life of natural diamond wire drawing die is great, and it is the biggest problem.

Mold size range: 0.015mm~2.00mm

Recommended to do the finished mold (Chu Xianmo), the filament mold, wire surface requirements of special bright mold.

Applicable to non-ferrous metal wire drawing platinum and rhodium wire, gold, silver, copper, aluminum, molybdenum, nickel, tin plated copper, tungsten, copper and aluminum alloy material.

Scope of production:

aperture(mm)

| tolerance(μm)

| Roundness(μm)

| Shell size (Standard Specification) | |

| external diameter(mm) | thickness(mm) | |||

| <φ0.050 | 0.5 | 0.25 | 25 | 7 |

| φ0.050~0.199 | 1 | 0.5 | 25 | 8 |

| φ0.200~0.499 | 0.5 | 0.75 | 25 | 8 |

| φ0.500~0.999 | 2 | 1 | 25 | 10 |

| φ1.000~1.499 | 4 | 2 | 25 | 12 |

| φ1.500~2.500 | 5 | 2.5 | 25 | 12 |

The customer can specify the size of the shell and the size of the aperture.

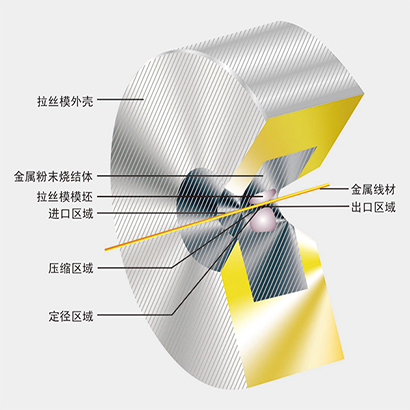

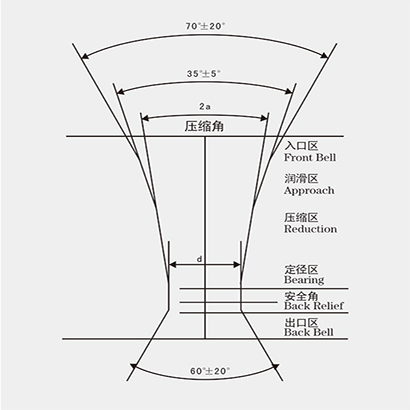

All kinds of wire standard hole design is as follows: (customers can also design Kong Xing)

wire rod | Hard wire

| Cords

| |||

Site name

| stainless steel | Copper clad steel

| Tungsten and molybdenum

| Copper wire

| aluminum steel

|

| entrance | 80° | 80° | 80° | 80° | 80° |

| Lubrication angle | 35° | 35° | 35° | 35° | 35° |

| Compression angle | 14°±2° | 14°±2° | 14°±2° | 14°±2° | 14°±2° |

| Parallel region | 0.2D~0.5D | 0.2D~0.6D | 0.2D~0.8D | 0.2D~0.5D | 0.2D~0.5D |

| Pressure relief angle | 25°±5° | 25°±5° | 25°±5° | 25°±5° | 25°±5° |

| exit | 60° | 60° | 60° | 60° | 60° |